• All Machines • FK Codingline

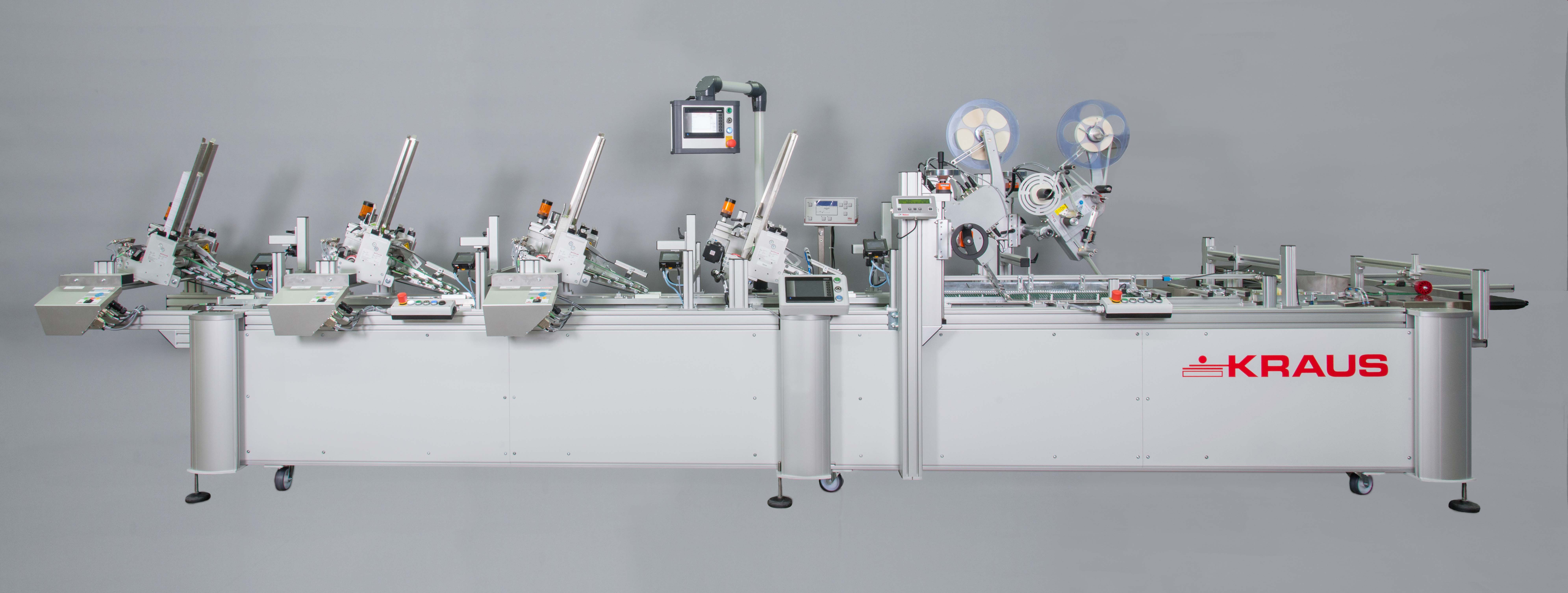

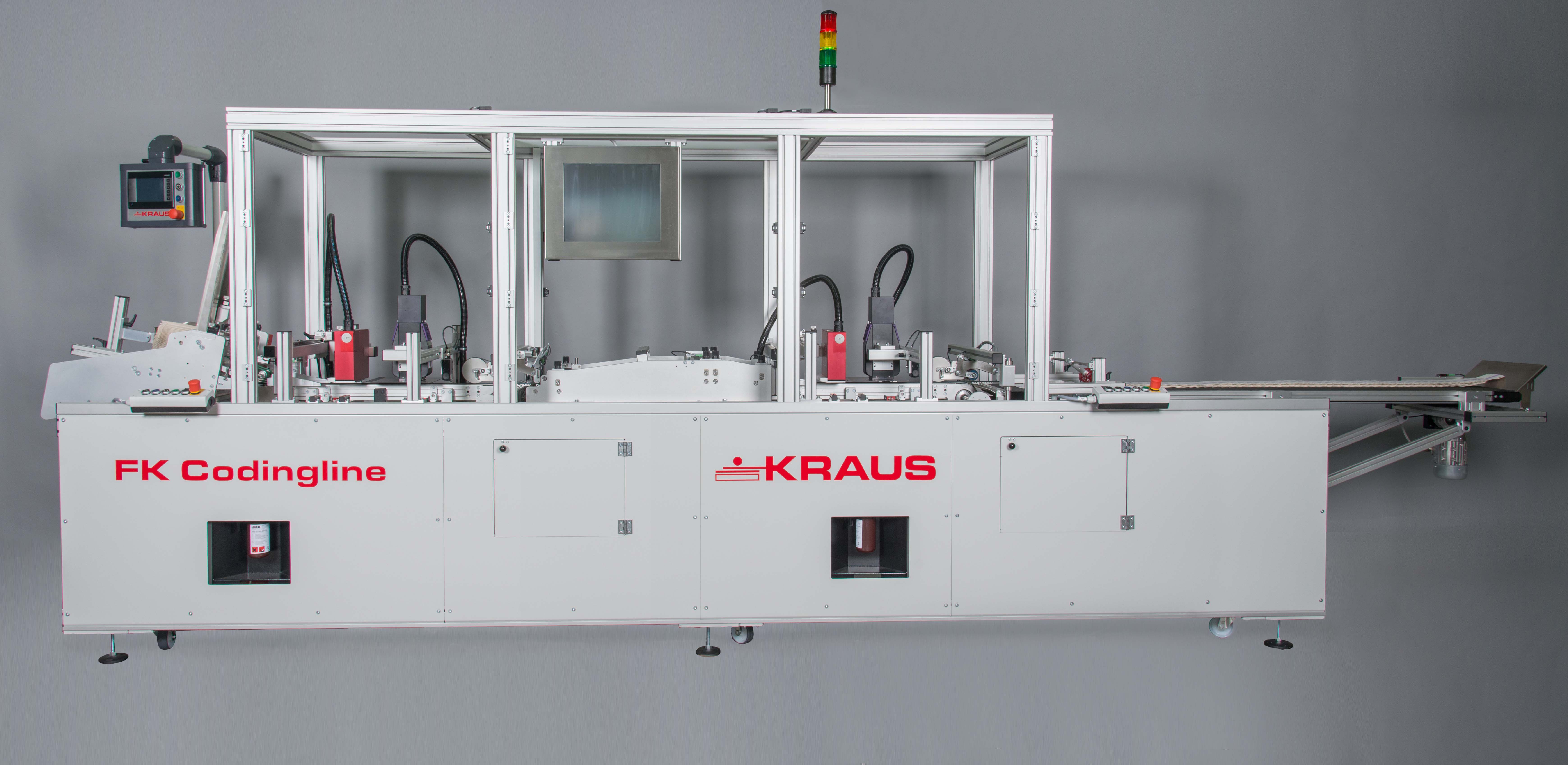

FK Codingline

About

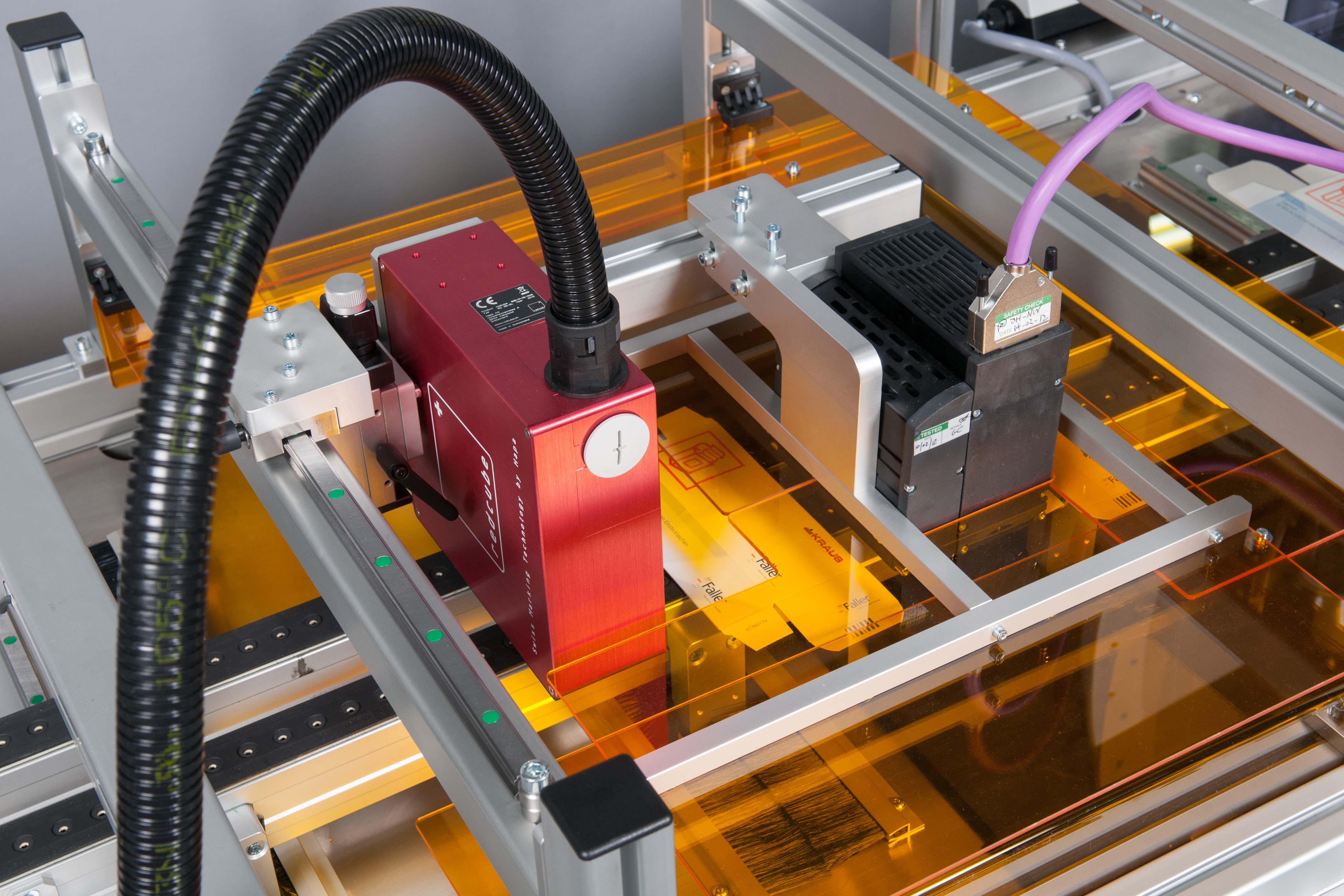

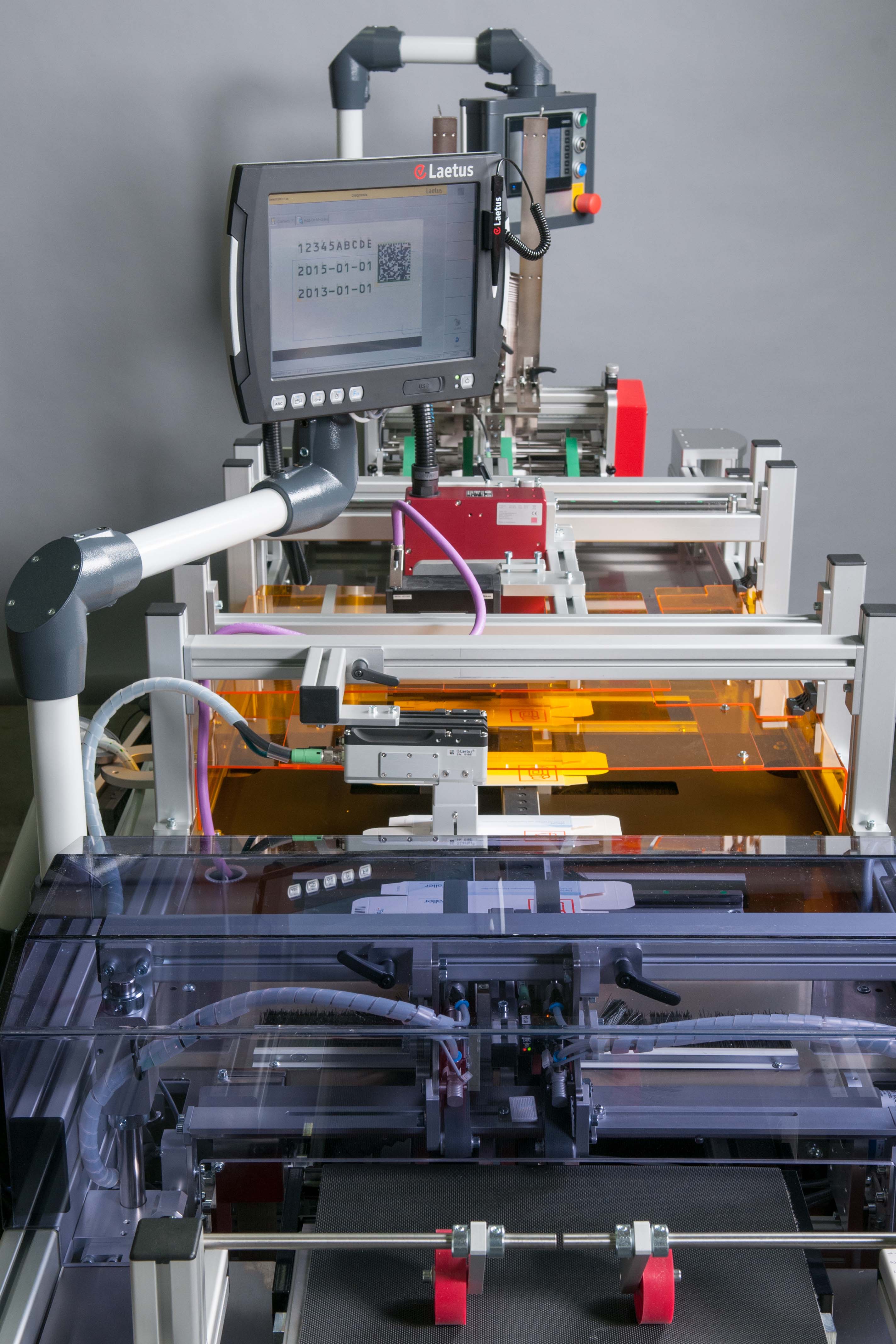

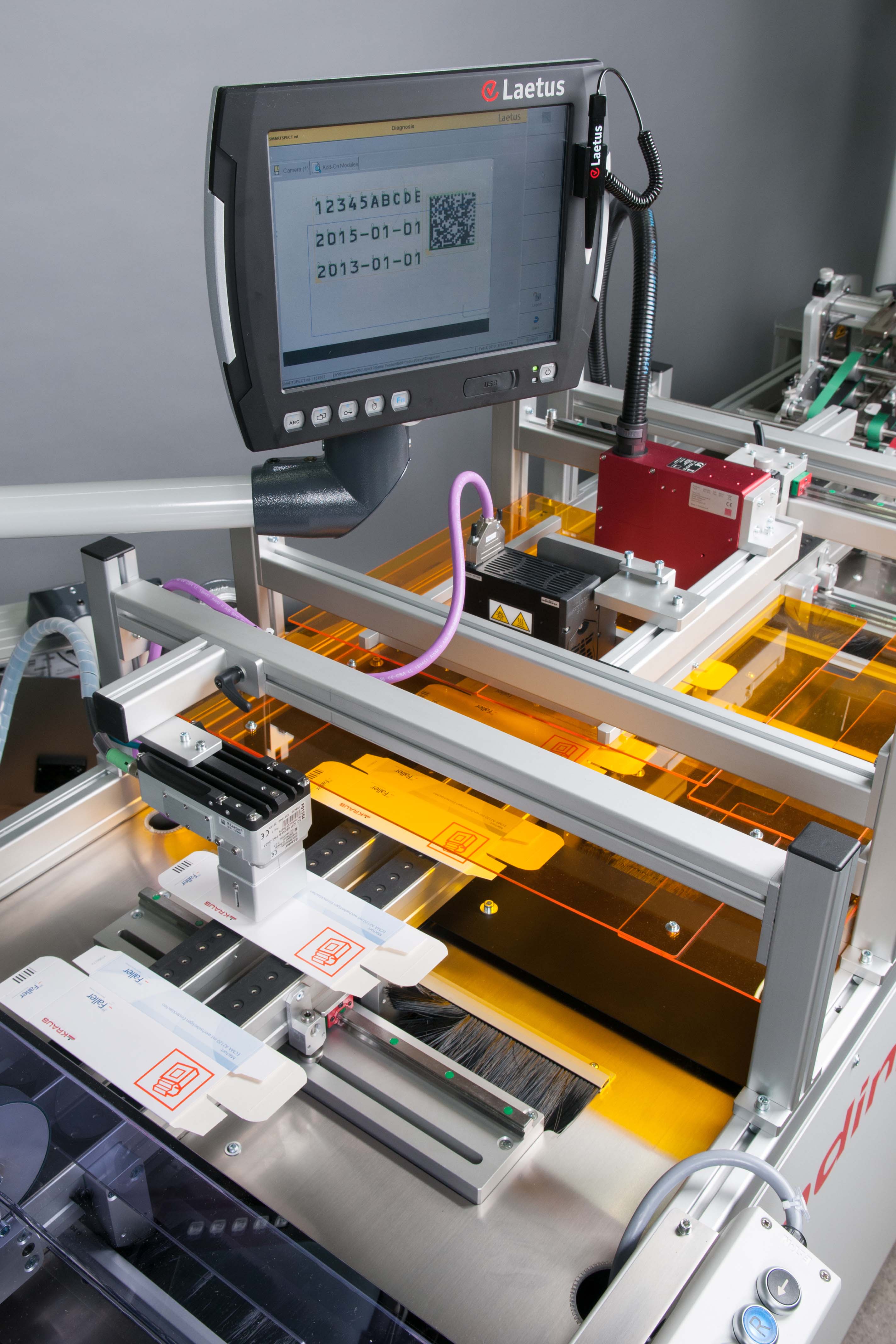

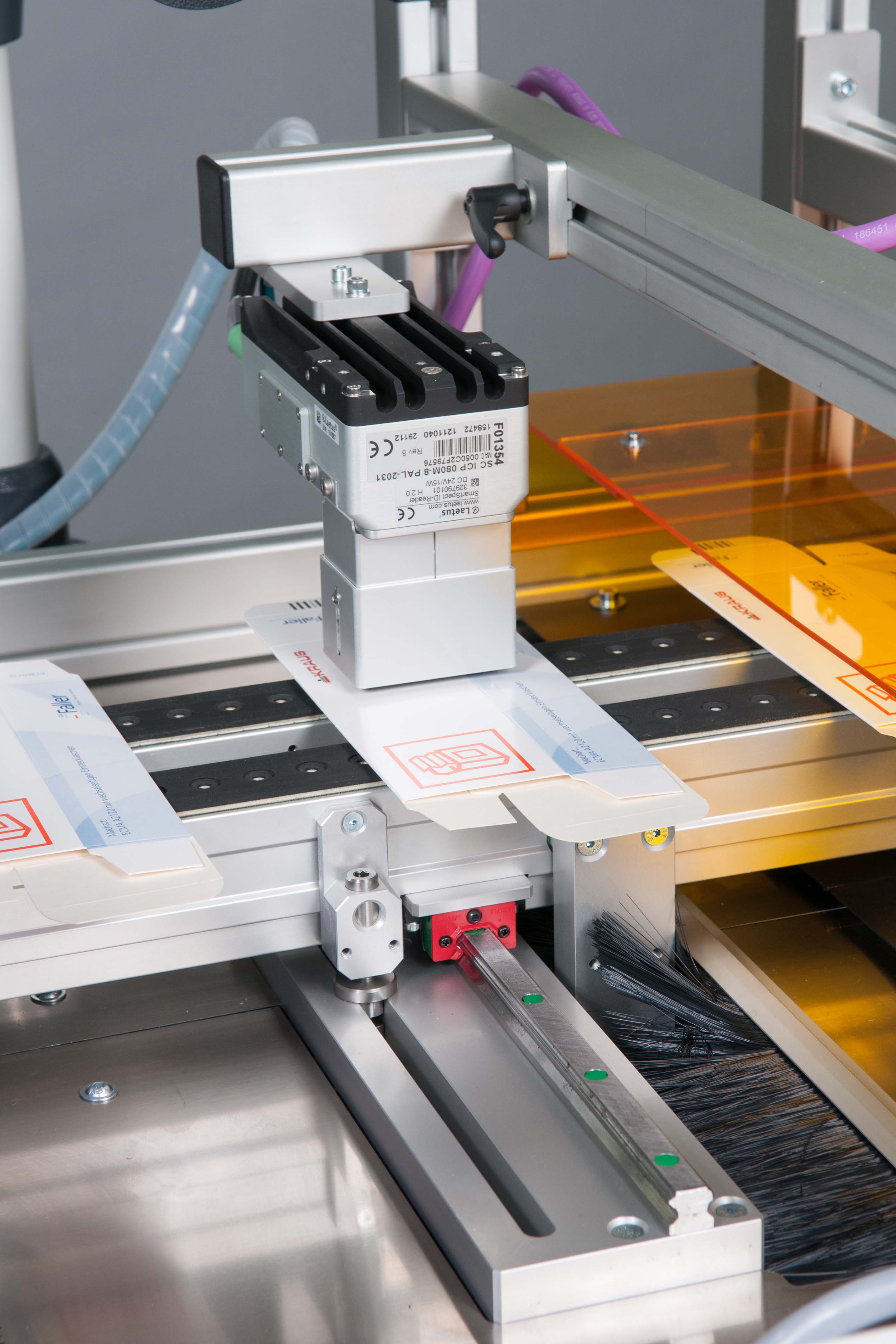

The machine's short tooling times and modular design make it versatile and economic to use with a variety of labeling methods. The printing line, with easily adjusted suction tracks, can cover a wide range of formats. The JoKer friction feeder, located on the face side, feeds the products reliably onto the suction conveyor. There, the vacuum conveyor conveys the carton boxes, either flat and open or already glued. The vacuum system allows the products to lie freely on the conveyor from where they can be printed or labeled wherever desired. The printing system then labels the folded boxes. A camera system is used to check the code and manage it in the database. If the camera does not read the product as correct, an impulse is issued to the automatic rejection unit and the defective product is discharged downward to a special catch box. Good products are transferred to the shingle outfeed conveyor, from where they can be removed manually

Videos

See on more YouTube